- Oil and Gas Industry

- Marine & Industrial

- Fertilizers Industry

- Pharmaceuticals industies

- Aircraft Industry

- Desalination Plants

- Paper & pulp Industries

- Nuclear power plant

ASMT A691 Alloy Steel Pipe Manufacturer in India

Table OF Content

- ASMT A691 Alloy Chromoly Steel Pipe Preview

- Specification Of ASMT A691 Alloy Steel Boiler Pipe

- Type Of ASMT A691 Alloy Steel Pipe

- Grades Of ASMT A691 Alloy Steel Pipe

- Packaging of ASMT A691 Alloy Steel 310S Pipe

- Application of ASMT A691 Alloy Steel Round Pipe

- ASMT A691 Alloy Steel Seamless Pipe Chemical Composition

- ASMT A691 Alloy Steel Polished Pipe Mechanical Properties

- ASMT A691 Alloy Steel Hydraulic Pipe Dimension

- High Temperature ASMT A691 Alloy Steel Pipe

- ASMT A691 Alloy Steel Pipe Stock Available

- City We Supply ASMT A691 Alloy Steel Pipe

- Countries We Supply ASMT A691 Alloy Steel Pipe

ASME SA691 Alloy Steel EFW Welded Pipes Supplier, High Pressure ASTM A691 Boiler Pipe Stockist, ASTM A335 P9 Pipes Manufacturer, ASTM SA691 P1 Pipes Supplier, ASTM SA691 P5 Pipes, ASTM SA691 P2 Pipes Stockist, ASTM A691 Alloy Steel ERW Pipe Manufacturer in india

Sumer Metal Corporation is an acknowledged Alloy Steel P91 Pipe Manufacturer in India, and it is known for manufacturing high-quality ASMT A691 Alloy Steel Pipes, which are of ISO and international quality. High and advanced technology is used in our manufacturing process to assure precision, durability, and high performance under tough conditions. Our grades are varied, and we have Schedule 80 Alloy Steel P91 Pipe and Schedule 160 Alloy Steel P91 Pipe, which are used in high-pressure and high-temperature applications. Moreover, our Schedule XXS Alloy Steel P91 Pipe can be used in such industries as Power Generation, Petrochemical, and Oil and Gas. The ASMT A691 Alloy Steel Pipes are designed to supplied reliability and efficiency in different fields of application.

ASTM A691Steel Pipe Supplier, ASME SA691 Alloy Steel Pipe, ASTM A691 9CR Cl22 Steel Pipe Stockist, Alloy Steel ASME SA 691 Pipes, ASTM A691 Grade 2.1/4cr Round Pipe Supplier, ASTM A691 5CR Cl22 Cold Drawn Pipe Supplier in India

Sumer Metal Corporation is a reliable ASTM A691 Alloy Steel Pipe Manufacturer & Supplier in India that manufactures high tensile piping solutions to withstand high temperature and pressure situations. We provide customization of sizes and length, such as diameters between 1/2 inch to 24 inches and a length of 12 meters, among others, depending on the project requirements. We have ASTM A691 Grade 2.1/4Cr Round Pipe and ASME SA691 Alloy Steel Pipe, which are made by cold and hot roll processes to achieve high structural performance. All our batches are subjected to rigorous Chemical & Mechanical Tests, like checking of hardness and tensile strength, and we also supply ASTM A691 5Cr Cl22 Cold Drawn Pipe in different material grades. We are also Leading Alloy Steel P91 Pipe Manufacturer in India.

Specification Of ASMT A691 Alloy Steel Pipe

| ASTM A691 Alloy Steel Pipe | Specifications |

| Pipe Standard | ASTM A691 ASME SA691 |

| Pipe Dimension | ANSI/ASME B36.19M, ANSI/ASME B36.10M |

| Pipe Sizes | 1 / 2" NB - 24" NB |

| Pipe Outside Diameter | 6.00 mm OD up to 914.4 mm OD, Sizes up to 24” NB available Ex-stock, OD Size Steel Tubes available Ex-stock |

| Steel Pipe Manufacturing Process | Seamless / Welded / Fabricated / CDW / 100% X Ray Welded |

| Alloy Steel Pipe Schedule | SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS, SCH XS |

| Pipe Ends | Half Hard, Soft, Hard, Quarter Hard, Spring Hard |

| Delivery Condition | Annealed and Pickled, Polished, Bright Annealed, Cold Drawn |

| Value Added Services | Cutting, Beveling, Polishing, Threading, Destructive, Non Destructive, Ultrasonic Testing |

Types Of ASMT A691 Alloy Steel Pipe

ASTM A691 ERW Pipe

ASMT A691 Welded Pipe

ASMT A691 Rounded Pipe

ASMT A691 Polished Pipe

ASMT A691 Chromoly Pipe

ASMT A691 SAW Alloy Steel Pipe

ASMT A691 Hollow Pipe

ASMT A691 Alloy Steel EFW Welded Pipes

ASMT A691 Cold Drawn AS Pipe

Get A Free Quote Now

Get Alloy Steel Pipe At Best Price in Mumbai, India !!

Grades Of ASMT A691 Alloy Steel Pipe

Alloy Steel P22 Pipe

Alloy Steel P12 Pipe

Alloy Steel P11 Pipe

Alloy Steel P9 Pipe

Alloy Steel P5 Pipe

Alloy Steel P1 Pipe

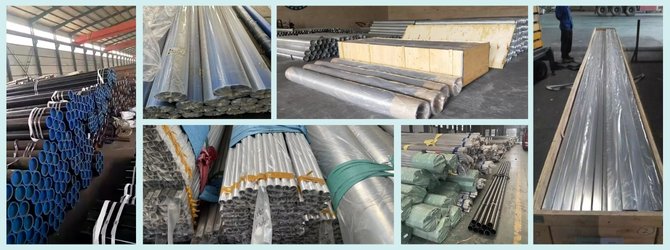

ASMT A691 Alloy Steel Pipe Packaging for Domestic Transit

- Bundles with Plastic Strips

- End Capping

- Colour-Coded Straps

- Bubble Sheet Plastic Wrap

- Loose Packing

International ASMT A691 Alloy Steel Pipe Pipe Export Packaging

- Wrapped in Plastic film or PVC sleeves

- Plastic End Capping

- Box Strapping

- Steel-banded wooden skids

- Wooden Box / Crate Packaging

Kindly note: Custom Packing is also available as per client requirements.

Mumbai ports or Nhava Sheva port in the Maharashtra state of India.

#Delivery ConditionAnnealed and Pickled (AP), Mirror Polish, Bright Annealed (BA), Matt Polish, Cold Drawn.

#Marking On PipesSize, Grade / material, Specification, Heat number.

#HSN CodeHsn Code of Stainless Steel Pipes is 7305 (first four digits).

#Testing Facilities

- Tensile Testing Machine

- Hardness Testing Machine

- Portable Hardness Tester

- Hydrostatic Test Machine

#Payment Terms

- Flexible payment options (Advance / Part Payment / LC / T/T)

- Transparent pricing structure with no hidden charges

- Easy & secure online/offline transaction facilities

- GST invoice & MTC Reports on every orders.

Sumer Metal Corporation believes that transparency and trust are very important whenever we engage in our transactions.

Application Of ASMT A691 Alloy Steel Pipe

ASMT A691 Alloy Steel Pipe Chemical Composition

| 1CR | 1-1/4CR | 2-1/4 CR | 5 CR | 9 CR | 91 | |

| C | 0.05-0.17 | 0.05-0.17 | 0.05-0.15 | 0.15 | 0.15 | 0.08-0.12 |

| Mn | 0.40-0.65 | 0.40-0.65 | 0.30-0.60 | 0.30-0.60 | 0.30-0.60 | 0.30-0.60 |

| P | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.020 |

| S | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.010 |

| Si | 0.15-0.40 | 0.50-0.80 | 0.50 | 0.50 | 1.00 | 0.20-0.50 |

| Cr | 0.80-1.15 | 1.00-1.50 | 2.00-2.50 | 4.00-6.00 | 8.00-10.00 | 8.00-9.50 |

| Mo | 0.45-0.60 | 0.45-0.65 | 0.90-1.10 | 0.45-0.65 | 0.90-1.10 | 0.85-1.05 |

| V | – | – | – | – | 0.04 | 0.18-0.25 |

ASMT A691 Alloy Steel Pipe Mechanical Properties

| Class | Heat Treatment on Pipe Section see: |

Radiography, see Section |

Pressure Test, see : |

| 10 | none | none | none |

| 11 | none | 9 | none |

| 12 | none | 9 | 8.3 |

| 13 | none | none | 8.3 |

| 21 | stress relieved, see 6.3.1 | none | none |

| 21 | stress relieved, see 6.3.1 | 9 | none |

| 22 | stress relieved, see 6.3.1 | 9 | 8.3 |

| 23 | stress relieved, see 6.3.1 | none | 8.3 |

| 31 | normalized, see 6.3.2 | none | none |

| 31 | normalized, see 6.3.2 | 9 | none |

| 32 | normalized, see 6.3.2 | 9 | 8.3 |

| 33 | normalized, see 6.3.2 | none | 8.3 |

| 40 | normalized and tempered, see 6.3.3 | none | none |

| 43 | normalized and tempered, see 6.3.3 | 9 | none |

| 43 | normalized and tempered, see 6.3.3 | 9 | 8.3 |

| 43 | normalized and tempered, see 6.3.3 | none | 8.3 |

| 50 | quenched and tempered, see 6.3.4 | none | none |

| 51 | quenched and tempered, see 6.3.4 | 9 | none |

| 52 | quenched and tempered, see 6.3.4 | 9 | 8.3 |

| 53 | quenched and tempered, see 6.3.4 | none | 8.3 |

| 60 | normalized and precipitation heat none none treated | none | none |

| 61 | normalized and precipitation heat none none treated | 9 | none |

| 62 | normalized and precipitation heat none none treated | 9 | 8.3 |

| 63 | normalized and precipitation heat none none treated | none | 8.3 |

| 70 | normalized and precipitation heat none none treated | none | none |

| 71 | normalized and precipitation heat none none treated | 9 | none |

| 72 | normalized and precipitation heat none none treated | 9 | 8.3 |

| 73 | normalized and precipitation heat none none treated | none | 8.3 |

ASMT A691 Alloy Steel Pipe Dimension Chart

| NPS (inch) | OD (inch) | OD (milimeter) | Wall thickness (inch) | Wall thickness (milimeter) | Weight (lb/ft) | Weight (kilogram/m) |

| 2 | 2.375 | 60.3 | 0.154 | 3.91 | 3.65 | 5.44 |

| 1/4 | 0.540 | 13.7 | 0.088 | 2.24 | 0.42 | 0.84 |

| 4 | 4.500 | 114.3 | 0.237 | 6.02 | 10.79 | 16.07 |

| 3/4 | 1.050 | 26.7 | 0.113 | 2.87 | 1.13 | 1.69 |

| 1 1/4 | 1.660 | 42.2 | 0.140 | 3.56 | 2.27 | 3.39 |

| 10 | 10.750 | 273.0 | 0.365 | 9.27 | 40.48 | 60.31 |

| 3 | 3.500 | 88.9 | 0.216 | 5.49 | 7.58 | 11.29 |

| 18 | 18 | 457.0 | 0.562 | 14.27 | 104.67 | 155.80 |

| 6 | 6.625 | 168.3 | 0.280 | 7.11 | 18.97 | 28.26 |

| 24 | 24 | 610.0 | 0.688 | 17.48 | 171.29 | 255.41 |

| 14 | 14 | 355.6 | 0.375 | 11.13 | 54.57 | 94.55 |

ASMT A691 Alloy Steel Pipe Tolerance on Length

| Length L | Tolerance on exact length |

| 6000 < L < 12 000 | +15 |

| L < 6000 | +10 |

| L > 12 000 | + by agreement |

ASMT A691 Alloy Steel Pipe Stock Available

- ASTM A335 P1 Alloy Pipes

- ASTM A335 P2 Alloy Pipes

- ASTM A335 P5 Alloy Pipes

- ASTM A335 P9 Alloy Pipes

- ASTM A335 P11 Alloy Pipes

- ASTM A335 P12 Alloy Pipes

- ASTM A335 P22 Alloy Pipes

- ASTM A335 P91 Alloy Pipes

- ASTM A335 P92 Alloy Pipes

- ASTM A213 T1 Alloy Tubes

- ASTM A213 T2 Alloy Tubes

- ASTM A213 T5 Alloy Pipes

- ASTM A213 T5B Alloy Pipes

- ASTM A213 T5C Alloy Pipes

- ASTM A213 T9 Alloy Pipes

- ASTM A213 T11 Alloy Pipes

- ASTM A213 T12 Alloy Pipes

- ASTM A213 T22 Alloy Pipes

- ASTM A213 T23 Alloy Pipes

- ASTM A213 T91 Alloy Pipes

- ASTM A213 T92 Alloy Pipes

- Alloy Steel Dairy Pipe

City We Supply ASMT A691 Alloy Steel Pipe

| City We Supply ASMT A691 Alloy Steel Pipe | |||||

| Mumbai | Ahmedabad | Jaipur | Surat | Pune | Delhi |

| Bhubaneswar | Gujarat | Gandhinagar | Kerala | Indore | Rajahmundry |

| Bhosari | Vijayawada | Firozabad | Nagpur | Rajkot | Bharuch |

| Noida | Raipur | Chennai | Hyderabad | Kolkata | Agra |

| Moradabad | Jabalpur | Jalandhar | Ludhiana | Prayagraj | Durgapur |

| Peenya | Pimpri-Chinchwad | Channapatna | Kharagpur | Nashik | Bareilly |

| Varanasi | Haldia | Rourkela | Bangalore | Moradabad | Ranchi |

| Patna | Trivandrum | Tiruppur | Vasai | Angul | Gawlior |

| Coimbatore | Kanpur | Bokaro Steel City | Vadodara | Navi Mumbai | Jabalpur |

Countries We Supply ASMT A691 Alloy Steel Pipe

| Countries We Supply ASMT A691 Alloy Steel Pipe | |||||

| South Africa | Sharjah | Africa | Nepal | Bahrain | Kuwait |

| Oman | Qatar | Saudi Arabia | United Arab Emirates | Taiwan | Nigeria |

| New Zealand | Australia | Venezuela | Israel | Japan | UAE |

| Algeria | Brazil | Mexico | Canada | United States | Russia |

| Poland | Belgium | Denmark | Norway | Sweden | Netherlands |

| United Kingdom | France | Spain | Italy | Germany | Afghanistan |

| Sri Lanka | Iraq | Philippines | Vietnam | Indonesia | Thailand |

| Malaysia | Singapore | Egypt | Yemen | Turkey | Iran |

| India | South Korea | Maldives | Switzerland | Myanmar | Angola |

-

Contact Person

Sanjay.M.Doshi

+91 98921 50263 -

Email

-

Address

Shop No. 8, Lad Niwas, 44/62, Ardeshir Dady Street, Mumbai - 400 004

Our Products

Steel Pipe

- Stainless Steel Seamless pipe

- Stainless Steel Welded Pipe

- Stainless Steel ERW Pipe

- Stainless Steel Oval Pipe

- Stainless Steel Hydraulic Pipe

- Stainless Steel Pipe for Thermocouple

- Corrugated Stainless Steel Pipe

- Stainless Steel Electropolished Pipe

- Stainless Steel Square Pipe

- Marine Grade Stainless Steel Pipe

- Stainless Steel Hollow Pipe

Carbon Steel Pipe

Alloy Steel Pipe

Stainless Steel Tube

- Stainless Steel Instrumentation Tube

- Stainless Steel Elliptical Tube

- Stainless Steel Capillary Tube

- Stainless Steel Polished Tubes

- Stainless Steel Round Tube

- Stainless Steel Coil Tube

- Stainless Steel Precision Tubing

- Stainless Steel Small Diameter Tubes

- Marine Grade Stainless Steel Tube

- Stainless Steel Hydraulic Tube